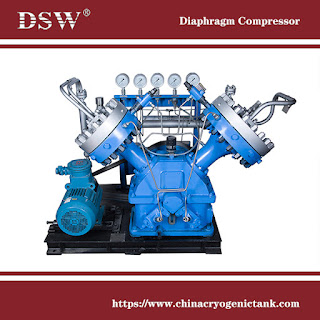

Argon Diaphragm Compressor

DSW Argon Diaphragm Compressors: Safe, Reliable Solutions for High-Purity Gas Handling

DSW's Argon Diaphragm compressors are ideal for applications requiring safe and efficient handling of ultra-pure, corrosive, and volatile gases. These compressors offer several key advantages:

- Leak-Free Design: Unlike traditional piston compressors, diaphragm compressors eliminate the risk of gas leakage into the atmosphere. This makes them perfect for handling hazardous or toxic gases, and protecting personnel and the environment.

- High Purity Compression: Diaphragm compressors achieve oil-free compression, preventing contamination of the compressed gas. This is crucial for applications requiring ultra-high-purity gases, such as electronics manufacturing or speciality gas production.

|

| Argon Diaphragm Compressor |

- API 618 Compliance: All DSW models can be designed to meet API 618 standards, ensuring adherence to industry best practices for safe and reliable diaphragm compressor operation.

- Customizable Configurations: DSW offers flexible configurations and sizes for various application needs. These compressors find use in hydrogen processing, petrochemical refining, electronic gas production, and polysilicon manufacturing.

- Compressor:

- Model: GV-25/7-150

- Medium: Argon (Ar)

- Type: V-style high-pressure diaphragm compressor with two cylinders and two-stage compression

- Discharge capacity: 25 Nm3/h

- Discharge pressure: 15 MPa (G)

- Intake condition: 0.7 MPa (G)

- Rotate speed: 400 rpm

- Lube type: L-HM46 hydraulic oil (user-provided)

- Motor (optional):

- Model: YX3-132M-4

- Type: Three-phase asynchronous motor

- Rating Power: 7.5 kW

- Rating rotate speed: 1440 rpm

- Rating voltage: 380 V

- Rating frequency: 50 Hz

- Unit:

- Size (length × width × height): 1600 mm × 900 mm × 1200 mm

- Unit net weight: 1000 kg

- Petrochemical Industry

- Specialty Gas Production

- Energy Sector

- Silicon Manufacturing

- Research and Development (R&D)

- Pilot Plants

- Reduced Vibration and Noise: The hydraulic design minimizes vibrations, knocks, and noise during the compression process.

- Oil-Free Compression: The tight fit between the oil and gas sections prevents oil contamination of the compressed gas.

- Enhanced Sealing Performance: Diaphragm compressors offer superior sealing due to the oil injection process, leading to efficient gas compression.

- Minimal Wear and Tear: Diaphragm compressors experience minimal wear and tear during operation, ensuring long-term reliability.

DSW Diaphragm Compressor Features:

Typical Argon Diaphragm Compressor Components:

Applications for Diaphragm Compressors:

Due to their leak-free and high-purity compression capabilities, diaphragm compressors are ideal for various applications, including:

Advantages of DSW Diaphragm Compressors:

DSW: Your Partner in High-Purity Gas Compression Solutions

DSW goes beyond simply providing air compressor solutions. We offer comprehensive systems designed for handling toxic or rare gases, ensuring safety and optimal performance in these critical environments. Contact DSW today to discuss your specific gas compression needs and explore how our Argon Diaphragm compressors can add value to your operations.

Comments

Post a Comment